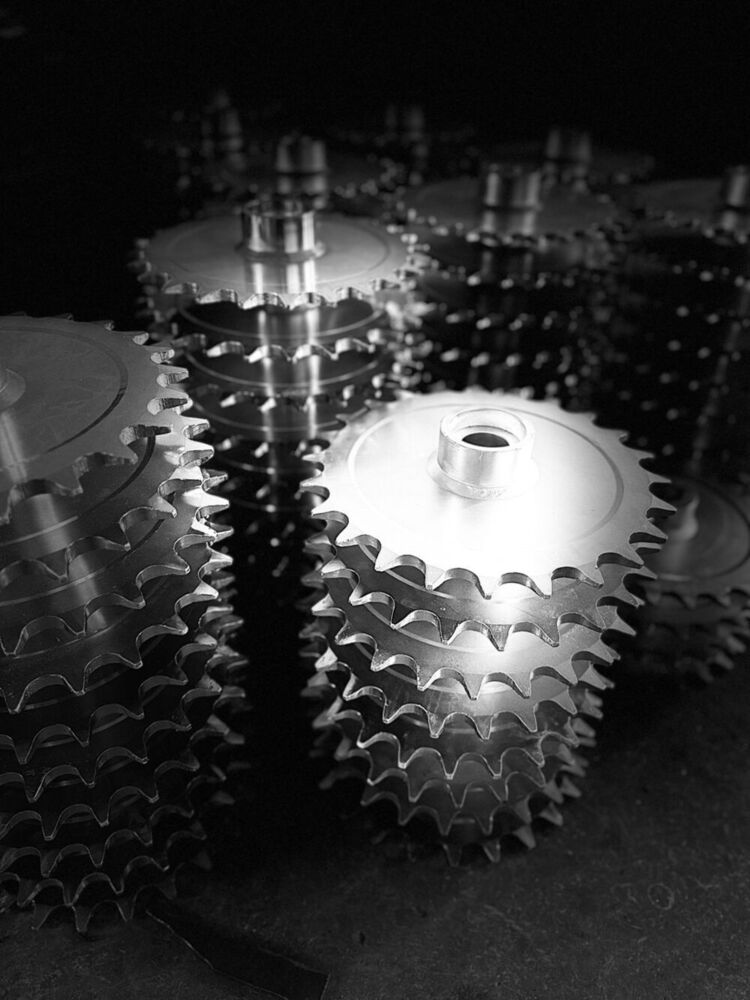

Z Elevator Sprocket

Price 900 INR/ Piece

MOQ : 10 Pieces

Z Elevator Sprocket Specification

- Usage & Applications

- Bucket Elevator Machinery

- Bore Size

- 30 mm

- Product Type

- Z Elevator Sprocket

- Material

- M.S. EN8

- Surface Treatment

- Blackodised

- Teeth Number

- 12

- Front Gear

- Available

- Rear Gear

- Available

- Warranty

- 1 year

- Size

- 8 Inch Outer Diameter (Approx.)

- Finish

- Precision Machined

- Shape

- Round

- Packing Type

- Wooden Box

- Customisation

- Available

- Manufacturing Technique

- CNC Machined

- Chain Compatibility

- Standard Elevator Chain

- Color

- Black

- Hardness

- 45-50 HRC

Z Elevator Sprocket Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

About Z Elevator Sprocket

Get It Now elevate your machinery performance with the praiseworthy Z Elevator Sprocket, crafted in India for masterful precision! Boasting a pristine black finish and round profile, this sprocket stands out at an unbeatable price. CNC machined from M.S. EN8 with superior hardness (45-50 HRC), it reliably fits standard elevator chains. The blackodised surface augments durability, ensuring industry-leading excellence for your bucket elevator. Customisation is available, supported by a 1-year warranty and secure wooden box packing. Trending now among professionals, choose Z Elevator Sprocket for assured quality!

Commercial Applications & Media Uses

The Z Elevator Sprocket is engineered for use in bucket elevator machinery, making it ideal for vital sectors such as agriculture, mining, and bulk material handling. Its compatibility with standard elevator chains permits efficient media movement of grains, minerals, or industrial products. Common places of installation include grain silos, processing plants, and warehouse conveyors where robust and dependable sprockets are essential for smooth and continuous operation.

FOB Port, Delivery & Export Markets

The Z Elevator Sprockets outlay is optimized for international buyers, with express shipping available from major FOB ports in India. Typical delivery time ranges from 7 to 15 days, depending on the export market and shipping mode. The sprocket is routinely exported to markets across Asia, Africa, the Middle East, and Europe, enabled by swift logistics and meticulous packaging for secure and timely arrival. Request export orders to experience hassle-free procurement.

Commercial Applications & Media Uses

The Z Elevator Sprocket is engineered for use in bucket elevator machinery, making it ideal for vital sectors such as agriculture, mining, and bulk material handling. Its compatibility with standard elevator chains permits efficient media movement of grains, minerals, or industrial products. Common places of installation include grain silos, processing plants, and warehouse conveyors where robust and dependable sprockets are essential for smooth and continuous operation.

FOB Port, Delivery & Export Markets

The Z Elevator Sprockets outlay is optimized for international buyers, with express shipping available from major FOB ports in India. Typical delivery time ranges from 7 to 15 days, depending on the export market and shipping mode. The sprocket is routinely exported to markets across Asia, Africa, the Middle East, and Europe, enabled by swift logistics and meticulous packaging for secure and timely arrival. Request export orders to experience hassle-free procurement.

FAQs of Z Elevator Sprocket:

Q: How does the precision machining improve the Z Elevator Sprockets performance?

A: Precision CNC machining results in finely crafted sprockets with exact specifications, minimizing wear and maximizing lifespan. Better fitting teeth ensure smoother chain movement, which translates to safer and more efficient bucket elevator operations.Q: What is the process for customising a Z Elevator Sprocket for particular requirements?

A: Buyers can specify customizations such as teeth number, bore size, or surface treatment. The manufacturer works closely to deliver tailor-made sprockets that meet specialised operational demands, ensuring optimal compatibility and performance.Q: Where is the Z Elevator Sprocket primarily used?

A: The sprocket is mainly installed in bucket elevator machinery found in industries like agriculture, mining, and industrial warehouse facilities. It facilitates vertical movement of materials, improving handling efficiency.Q: When can customers expect delivery after placing an order?

A: Express shipping options typically ensure delivery within 7 to 15 days from major Indian FOB ports, based on location and order volume. Buyers receive prompt dispatch and tracking for peace of mind.Q: What are the benefits of the blackodised surface treatment?

A: Blackodised treatment enhances corrosion resistance and durability, making the sprocket more robust against harsh working environments and ensuring a longer service life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Chain Sprocket Category

Chain Chakkar

Price 600 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Polished

Material : Stainless Steel

Product Type : Chains & Sprockets

Teeth Number : 25

Chain Sprocket

Minimum Order Quantity : 100 Pieces

Surface Treatment : Plain

Material : Steel

Product Type : Chains & Sprockets

Teeth Number : 20

Send Inquiry

Send Inquiry